Content

- Disadvantages of Just-in-Time Inventory Techniques

- Create Just-in-Time Manufacturing Processes on Kanban Boards

- Diversity and Inclusion Management: Billy Ray Taylor Shares Best Practices

- Factory Talk #10: Shannon Lindsey, Production Manager, Sandvik Coromant

- Lean Manufacturing Principles

- Is Just-in-Time Manufacturing Risky?

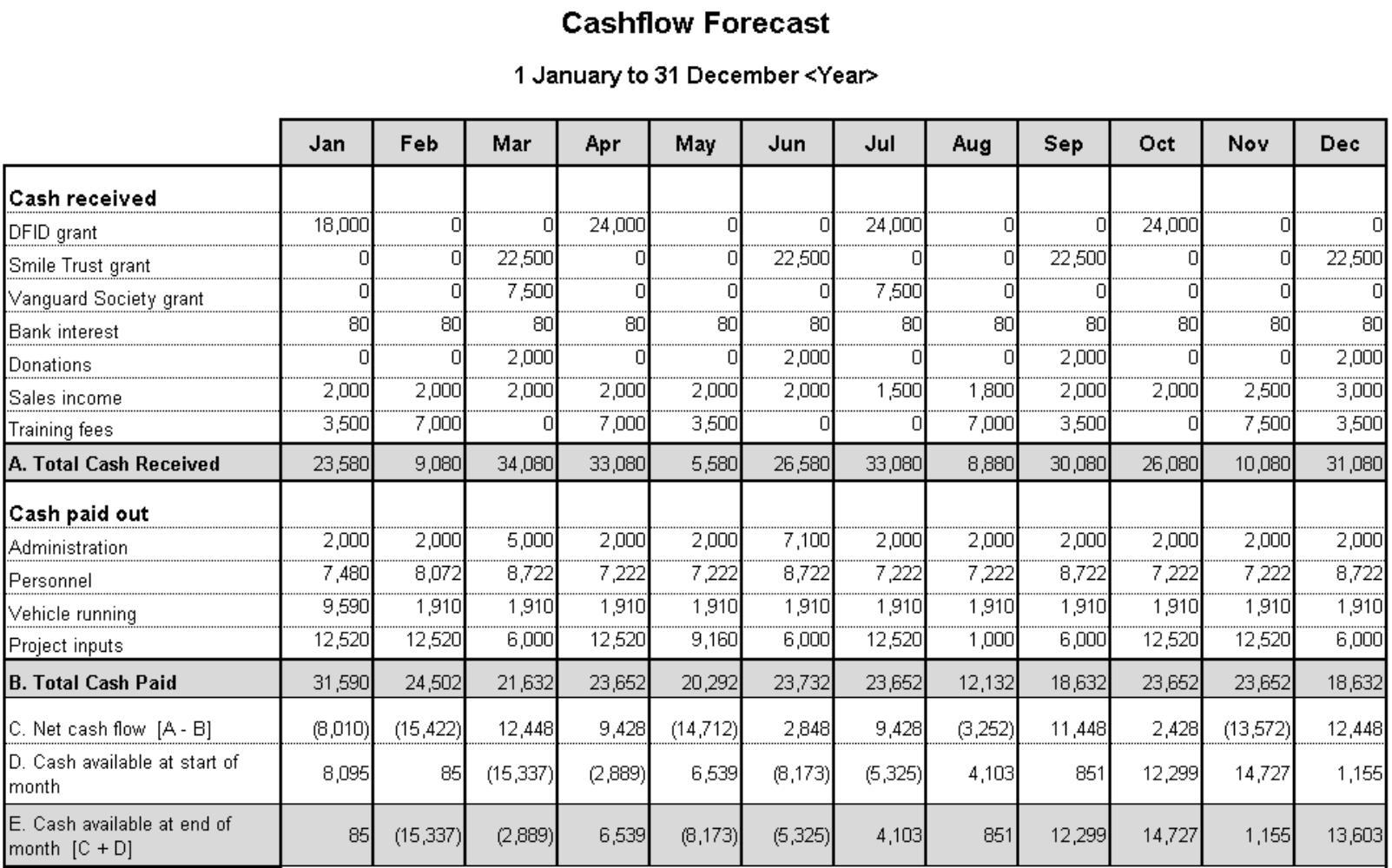

The approach was developed in post-World War II Japan, when car manufacturing faced shortages and had to minimize resource consumption to survive and remain competitive. Standardized Operations; only if you know how each operation is going to be performed can you be sure what the https://business-accounting.net/ reliable outcome will be. Defining standard ways of working for all operations will help to ensure that your processes are reliable and predictable. Within a Just in Time manufacturing system, each process will only produce what the next process in sequence is calling for.

Having raw materials arrive at a manufacturing facility, just in time to enter the production process allows an organization to minimize the amount of inventory What is Just-in-Time Manufacturing it must hold and store. It also minimizes the potential cost of obsolescence, which can arise due to change in product specifications, customer demands, etc..

Disadvantages of Just-in-Time Inventory Techniques

They inform each other and are mutually dependent on generating successful outcomes. Lead time reductions; one of the most significantly impacted areas is that of the time it takes for products to flow through the process. Instead of weeks or months most JIT implementations result in lead times of hours or a few days.

Indeed, the kanban method of posting circulating work orders makes the current work commitment of the manufacturing cell immediately obvious to everybody in the cell. Planning setups in advance, therefore, or opportunistically consolidating batches to save setups can become routine. The mix changes and demand surges that call for personnel reassignments become more transparent. Scheduling systems that can handle the complexity of detailed operational scheduling are only just appearing. Occasionally, if the production mix is changed, the rates may be changed, but these changes are infrequent. Since production rates are uniform and predictable, material can be delivered to the process in a JIT manner. Input your business details, select a challenge, and see the real-world cost impact as validated by our customers.

Create Just-in-Time Manufacturing Processes on Kanban Boards

JIT means that your production operations start with just enough time to be completed by the need date so that your goods are being produced to ship, not to be stored. One of the difficulties in implementing JIT is aligning the production line’s needs with the suppliers, as their performance and timeliness will strongly impact your implementation’s success. As close an understanding with your suppliers as possible is a must. If the orders contain errors, then due to the short lead time, mistakes will quickly make it into production, so fixing or changing an order can be impossible. Lastly, in case of an interruption in the supply chain, or a sudden problem with the suppliers, you won’t have a lot to fall back on in terms of redundant material piles.

- But, who is to say, had it not been for a once-in-a-lifetime pandemic, would JIT have failed?

- Since JIT is a stockless production and does not allow room for defects or error, having trustworthy reliable suppliers is an important factor.

- A 1993 book on «world-class distribution logistics» discusses kanban links from factories onward.

- And it is difficult to see the cost impact of one or more mistakes.

- Lean and JIT do not require physical investment, nor major cash injections.

- Indeed, as information technology evolves further, push techniques, like the pull approaches, will tend to decentralize control to the local, cell level.

- Constant communication with the customer results in high customer satisfaction.

The more consistent supply and demand are for a business, the more likely it is that they will be able to effectively employ JIT strategies. JIT supply chains can also be applied to many other operations a business may perform.